COVID19, aka Coronavirus, is taking its toll on all of us, in a variety of ways. So as I kick off an Editors Corner post here on AM News, I want to use it to update you on positive news all across the Additive Manufacturing and Materials Science communities.

People are coming together to 3D print, to sew (yes, handmade cloth DIY masks – more on this below, hang on), and explore and test materials for the certified N95 respirators and surgical masks. Plus, I will share a couple of stories from within our community of two educators working tirelessly to 3D print face shield parts for use by those on the front lines.

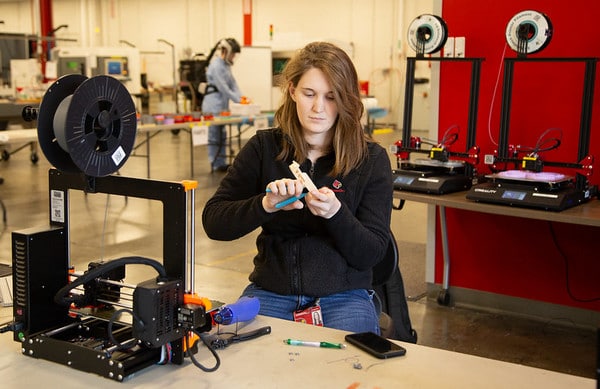

At Tennessee Tech University, Dr. Ismail Fidan and team have turned the university makerspace, STEM Center, and department labs into 24/7 3D print shops for COVID-19 protective face shield parts. The University also has a very well-established Additive Manufacturing Coalition and Hub established with an NSF award. Their network is also supporting the university’s efforts.

So far, they have printed 381 masks (as of March 25) that went to the state directly for final assembly and distribution to healthcare professionals. The TTU Department of Manufacturing and Engineering Technology and College of Engineering are running 30-plus 3D printers across the two labs. (Short video with them loading up a box of parts.). The Tennessee Tech team plans to keep printing since there are still more production requests and needs from the state.

University of Louisville runs one of the top Additive Manufacturing programs and has an amazing 3D printing facility for training and workforce development. I spent time there a few years back visiting Ed Tackett who runs it when I happened to be driving across the country (not 3DRV, another time). You can read more about their COVID-19 efforts here: Students Producing 3D Printed Face Shields For Healthcare Professionals. Ed is helping nationwide with people trying to sort out how to print at the highest possible quality and speed.

Normally, I do not cross-link (although there’s nothing wrong with doing it) between my work at Forbes and my National Science Foundation grant project work, but we are in uncharted waters and all the resources we can share with one another, well, it may save a life. If you have a project you are working on related to COVID-19, please get in touch and we will consider adding it here.

If you are looking for a way to get you or your students involved (great remote, work-from-home, learn-from-home potential), I encourage you to look over the different resources in these Forbes posts — there are many hands-on opportunities:

As I explained in Forbes, “I had, like many of you, planned to attend the RAPID + TCT event in Anaheim this year. SME, the parent organization that creates the RAPID + TCT event, wisely postponed the event. I have attended several of the RAPID + TCT events and it is always amazing to connect with the community; it is more like a large family reunion, frankly…” But now, thanks to what SME has built, those same people are still coming together to solve one of the world’s greatest challenges.

“If you ever wondered if 3D printing is all it claims to be, Coronavirus has helped settle that. 3D printers do all of this and more.”

Let’s close with two final examples of people coming together:

-

- MatterHackers, the largest distributor of desktop digital manufacturing equipment and materials in the USA, created an initiative called the COVID-19 Additive Manufacturing Community Response Hub and it will “connect those in the U.S. who need medical aid (Hospitals and Govt. Agencies) and those who can create it using Digital Manufacturing.” It has been live for three days and hundreds have signed up.

-

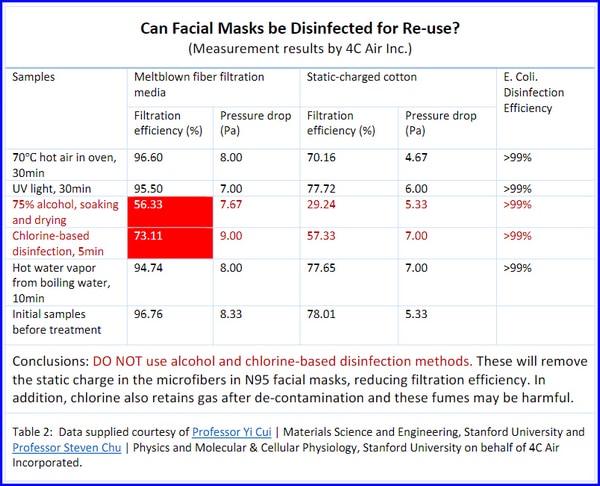

- The N95 respirator mask is a one-time use item. But healthcare professionals are being asked, all around the world, to keep using the same mask repeatedly. Stanford University has helped answer the question pulling in materials scientists: Can Facial Masks be Disinfected for Re-use? Amy Price, DPhil (Oxon) and Larry Chu, MD on behalf of the Stanford AIM Lab and Learnly COVID-19 Evidence Service Stanford Anesthesia Informatics and Media Lab found that it is possible. See their PDF (linked in the title above) if you are involved in any efforts to help healthcare professionals get access to N95 masks. Hint: 70°C hot air in oven, 30min (not a home oven, to be clear!). Read the PDF with loads of technical details.

Although we are living in challenging times, educators and researchers in the USA and internationally are working incredibly long hours to help and save others. Many of the TEAMM network members are working round the clock to provide much-needed Personal Protective Equipment (PPE) by 3D printing face shields based on an open source design using PETG filament material on a wide range of 3D printers.

Coronavirus may look like it is winning, but based on these stories and dedicated people, there is hope that it will soon be defeated.