The additive manufacturing program at Somerset Community College (SCC) recently 3D printed numerous 316L stainless steel metal parts on multiple low cost desktop 3D printers. Metal 3D printing is typically an expensive process requiring metal 3D printers starting in the low six figures. SCC has created an impressive initiative to bring the cost down – way down.

SCC’s process is based on a relatively well-known method known as “Bound Metal Additive Manufacturing” (BMAM). It is also predicted by researchers to be one of the fastest growing methods of additive production over the next several years. The SCC AM program faculty and staff started with several low-cost or fused filament fabrication (FFF) (sometimes known as fused deposition modeling – however, FDM is a trademarked term) 3D printers, typically less than $450 each, then modified them for metal filament extrusion and better build plate adhesion for an additional $150 each (total price tag of $600 per printer).

Once you print a part on one of the SCC machines, there are still multiple steps to completion. The team started with metal-infused filaments provided by Virtual Foundry and BASF. After accounting for shrinkage and other production issues in the design phase, the parts were 3D printed. SCC worked with sintering experts such as DSH Technologies to debind and sinter the 3D printed parts. Imagine that part is “green” and must be cured, similar to what you might do with a piece of pottery in a kiln (oversimplified, but you get the idea). Below, we link to a few additional resources from Virtual Foundry, BASF, and MatterHackers (a provider of filament).

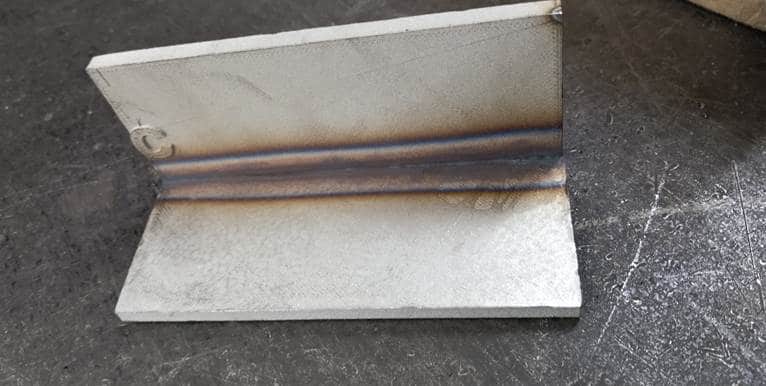

With the material hardened into something closer to its finished metal state, the team had SCC’s Welding department work on the parts. Senior Welding Professor, Karl Watson, used Gas Tungsten Arc Welding (GTAW), also known as TIG welding. Several fillet and groove welds were applied to the original six pieces and the welding went very well.

Preliminary testing of the parts has also shown hardness values slightly less than stock 316L (stainless steel), but microscopic inspection after finishing work has not shown any inconsistencies thus far. Watson also noted that the heat dissipation during the welding process of the 3D printed stainless was higher than conventional stock stainless.

From this success, SCC’s goal now is to bring this low cost metal 3D printing technology to students, teachers, and the workforce throughout Kentucky. SCC will be providing training workshops across the state in the assembly and set up of low cost metal 3D printers for select educators in Kentucky high schools and community colleges. This work is funded by the National Science Foundation (NSF) and EPSCoR (or Established Program to Stimulate Competitive Research) grants.

Over the next few months SCC will be dialing in the equipment and their training process for the low cost metal procedures, as well as collecting data on product performance. Eric Wooldridge, Director of SCC’s Additive Manufacturing program, notes that “there is a lot for us to learn about practical welding of 3D printed metal parts, especially parts that have been produced on a desktop 3D printer. Factors of shrinkage, potential zones of weakness, and the best welding practices are still to be determined. These are very exciting but uncharted waters to be sure.”

SCC will be working with partners across Kentucky, including the University of Louisville and the University of Kentucky, to integrate skills in low cost BMAM into the workforce. SCC will also be working with Tennessee Technological University (TTU) to scale their work across state lines through the support of the Mobile Additive Manufacturing Platform for 21st Century STEM Workforce Enhancement grant from the NSF Advanced Technological Education (ATE) program.

SCC currently offers a certificate in Additive Manufacturing/3D printing and offers additional training through the college’s Workforce Solutions program. For more information, please visit SCC’s Additive Manufacturing program, or check out their YouTube channel, The Additive Guru, dedicated to 3D printing.

Additional Resources:

-

-

- Virtual Foundry – makers of the sintering furnace

- BASF – makers of the metal filament mentioned above

- MatterHackers – a provider of filament and reseller of 3D printing machines and equipment. This link goes to a YouTube video overviewing the metal filament from BASF.

-