By now, it is fairly clear that the delivery of education has changed. With no in-person, on-campus classes and nearly everything online, we have moved into a new era, whether we like it or not. COVID-19 may soon be stopped by way of a vaccine, but its impact is undeniable.

Thanks to Dr. Ismail Fidan, Professor of the Department of Manufacturing and Engineering Technology at Tennessee Tech University, AM News started exploring what online learning looks like, on the ground, for the Spring semester and future ones. Since most of you were thrown into the virtual learning, distance learning, remote learning world (pick your term), we uncovered many great resources ideas we hope will help you plan and build your courses and teaching methods.

Dr. Fidan faces some of the same challenges that many professors face — how to teach an in-person lab when you cannot meet in person. He shared that he was able to build his own virtual lab, and help his colleagues with theirs, to develop materials for ZOOM and TTU’s use of Desire2Learn’s BrightSpace learning management system platform.

In the Plant Layout and Materials Handling course, students do their design work by accessing the virtual laboratory of Tennessee Tech, quickly developed by the Information Technology Services team. Using the commercial VMware Horizon application, students join the laboratory and complete their assignments remotely using AutoCAD 2020.

In the CNC Machining Practices course, students use the Autodesk Fusion 360 software tool (again via remote access). This is a cutting-edge simulation tool for CNC machining operations. Anything they program also functions the same as in real cutting operations.

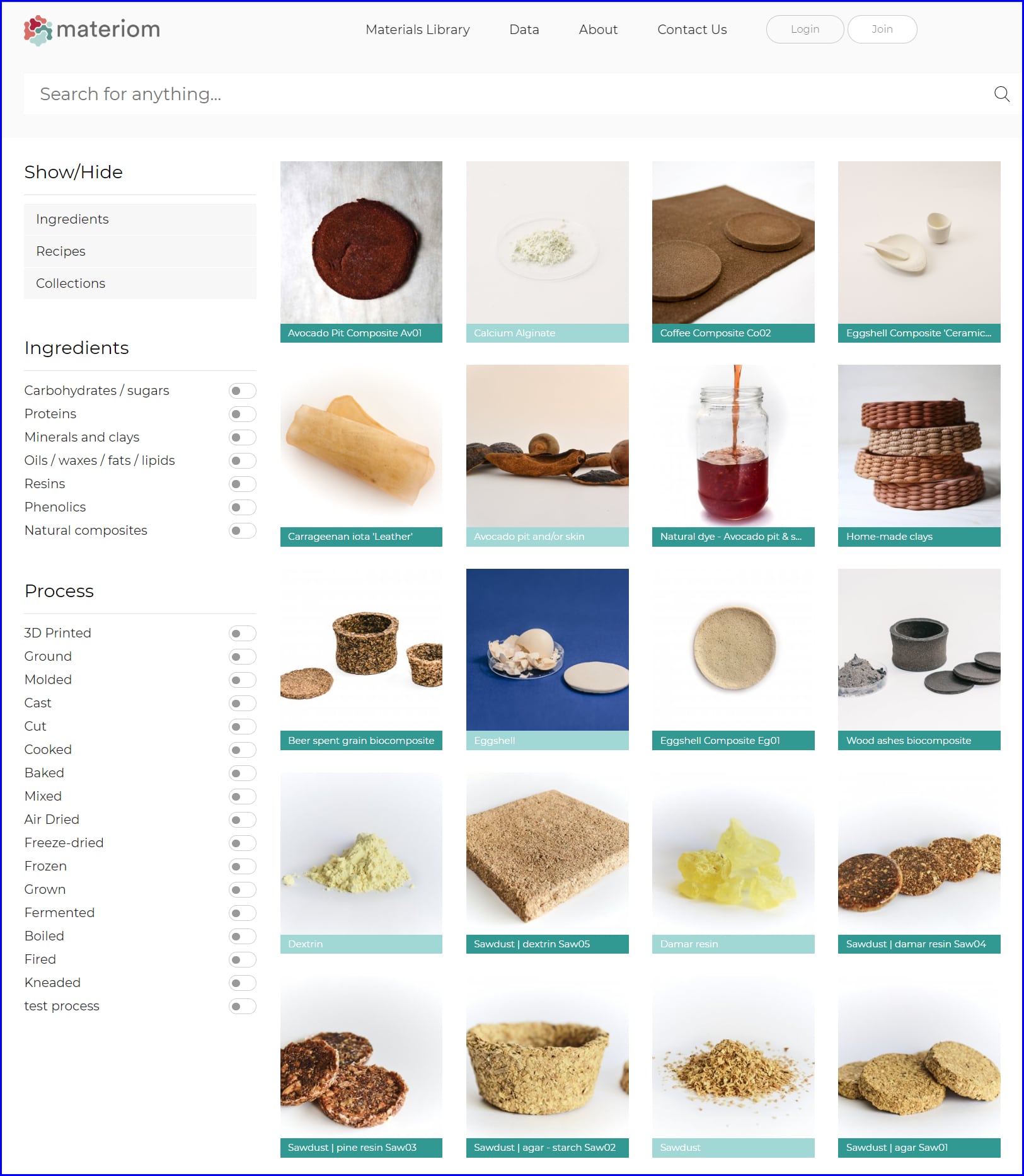

Although the MatEdU free resources were not built for remote learning specifically, you can find a wide range of materials science curricula that may guide your next steps to planning online courses. Visit the MatEdU Modules page or the Instructional Resources page. Here are five additional sites packed with even more ideas.

Regardless of which technology platform your school uses, here are several other resources that may provide useful tips and techniques:

- Inside Higher Ed: Adjusting to Remote Instruction at Community Colleges

- Edutopia: Distance Learning FAQ: Solving Teachers’ and Students’ Common Problems

- GettingSmart built a Getting Through portal of online resources.

- Wheaton College (Massachusetts): Center for Collaborative Teaching and Learning

- Finally, although this EdSurge article is from 2018, it links to Professor Michael Wesch’s YouTube channel and his amazing work in bridging the gap between online learning and what he calls “Teaching without Walls.” Read: How an Experimental Online Course Helped One Anthropology Department Keep a Professor and a Half.