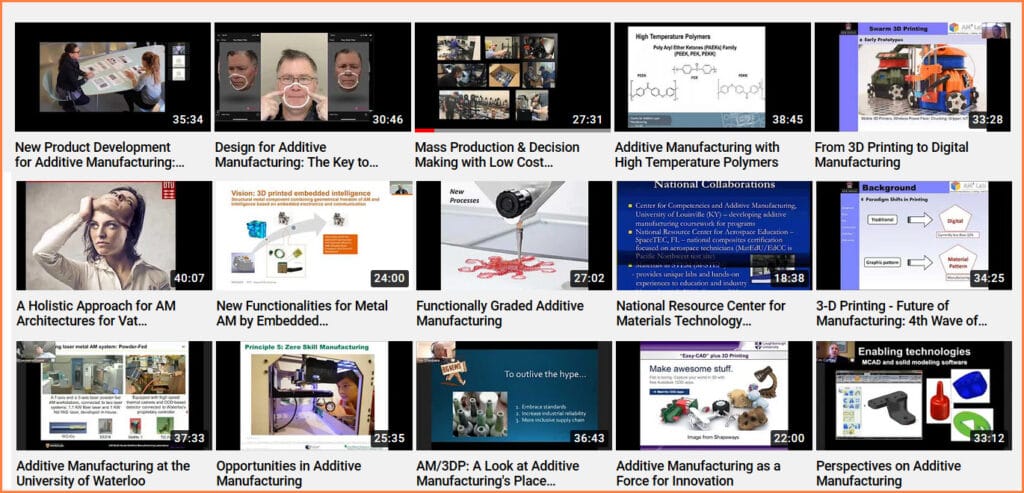

Keeping up with technology trends of any type is no easy feat, but maintaining pace with additive manufacturing would be near impossible without the help of the annual industry-leading report on additive manufacturing (AM) and 3D printing from Wohlers Associates, a TEAMM Coordination Network partner.

In the Wohlers Report 2021, now in its 26th year, is a detailed look at the trends, perspectives, and forecasts that executives and educators find essential for decision making, education, and knowledge acceleration. The report gives readers new to AM a comprehensive understanding of the technology and industry. Veterans of the technology benefit from up-to-date information on growth, recent trends, and important developments worldwide.

This year’s 375-page report discusses the impact of COVID-19 on the AM industry. Even with the pandemic, Wohlers Associates found industry expansion of 7.5 percent to nearly $12.8 billion in 2020. Growth was down considerably, compared to average growth of 27.4% over the previous 10 years.

Most established manufacturers of AM systems saw a decline in equipment sales, but many less-established companies grew in 2020. An increase in business by AM service providers supported industry wide growth. The following chart shows 7.1% growth from independent service providers worldwide, resulting in nearly $5.3 billion of revenue from this group.

Dr. Ismail Fidan, Professor in Manufacturing and Engineering Technology at Tennessee Tech University, is an associate author of Wohlers Report 2021. He focuses on Academic activities and capabilities, and in the section, he highlights the work of over 130 institutions and 15 research institutes, some examples:

- “Somerset Community College in Kentucky initiated a new AM project called the Rapid Response Additive Manufacturing Initiative (RRAMI). It involved a statewide rapid response network capable of manufacturing critical supplies in the event of future emergencies.” We shared an RRAMI update on LinkedIn related to our AM News social media efforts.

- “Five Louisiana universities have been awarded a $20 million grant from the National Science Foundation to transform AM research and education in Louisiana.”

- “The National Institute of Standards and Technology awarded nearly 4 million to Georgia Tech, the University of Texas at El Paso, Purdue University, and Northeastern University. The grant is to advance the competitive competitiveness of metal AM companies in the U.S.”

In addition to the academic section (and the rest of the regular comprehensive report sections), there are new and expanded features in Wohlers Report 2021:

- 3D printing of food, medicine, and electronics

- Pricing of metals and polymers and the hidden costs of AM

- Methods of AM part inspection

- Pandemic’s impact on the AM industry

- Compilation of expert reports from 34 countries

- Tables of AM systems, software tools, service providers, and third-party materials

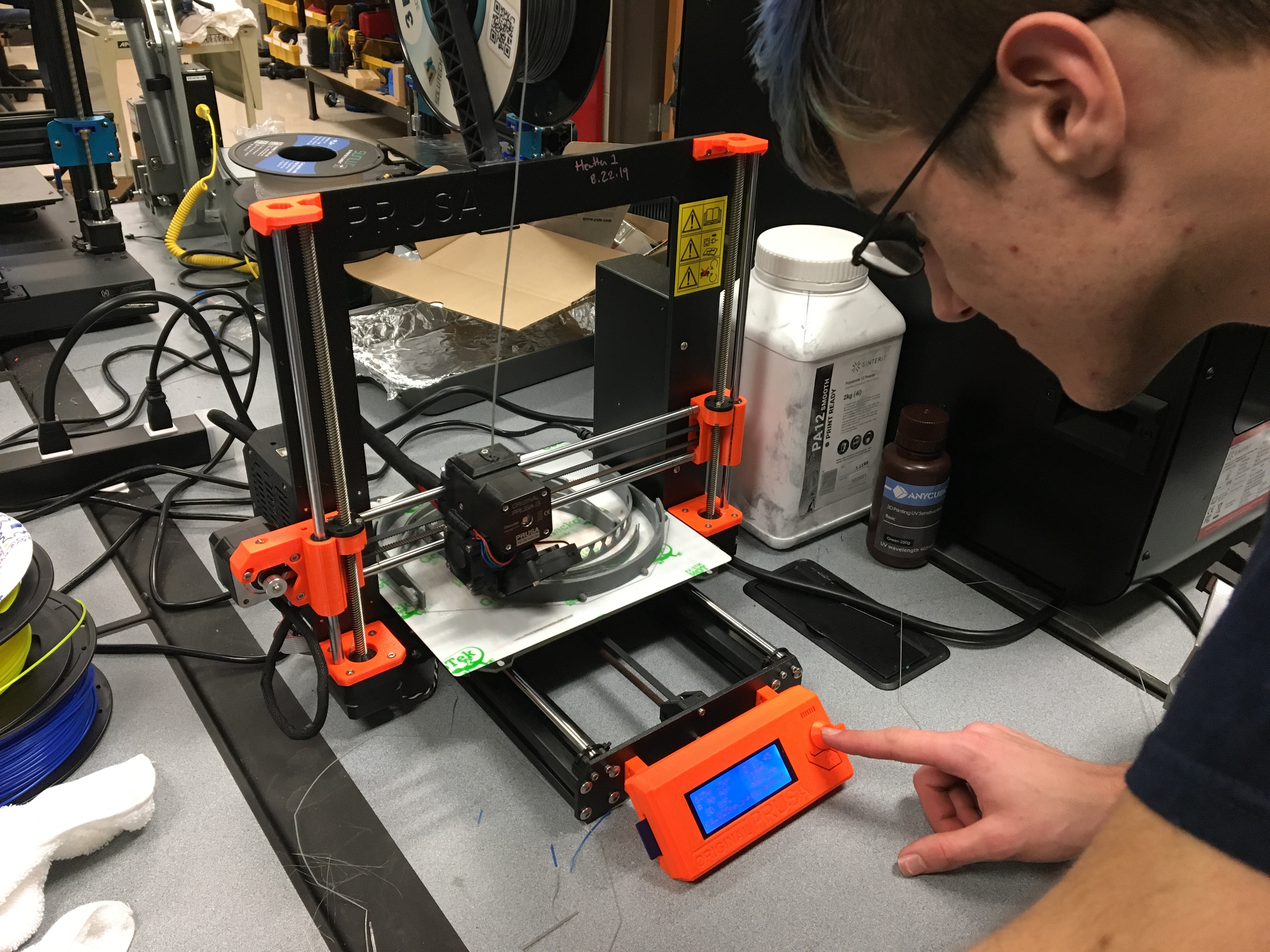

Of course, at TEAMM as well as MatEdU, we are particularly interested in the materials science and technician side of the industry and Wohlers Report 2021 has a dedicated section, 40-plus pages, on Materials and Processes. In the materials section, are explanations of the latest material processes, such as, vat photopolymerization, powder bed fusion, material jetting, binder jetting, and directed energy deposition, among others. There are deep dives into polymers, graphene and other nanomaterials, new polymer products as well as metal powders for metal AM. The section also explores various 3rd party material producers and talks about the Senvol public database of AM systems and materials.

If you are looking to understand the industry and its many fast-moving parts, Wohlers Report 2021 is a strong way to start (and finish). Read more about Wohlers Associates here.