The Maker Movement and the spawning of “MakerSpaces” around the world is still actively growing, despite COVID-19 and other obstacles to meeting in person. According to Dr. Ismail Fidan at Tennessee Tech University (TTU) and a team of authors (profiles linked below) publishing in Technologies journal, iMakerSpace Best Practices for Shaping the 21st Century Workforce, the TTU iMakerSpace became an essential part of their educational process.

Authors:

What Is A Makerspace?

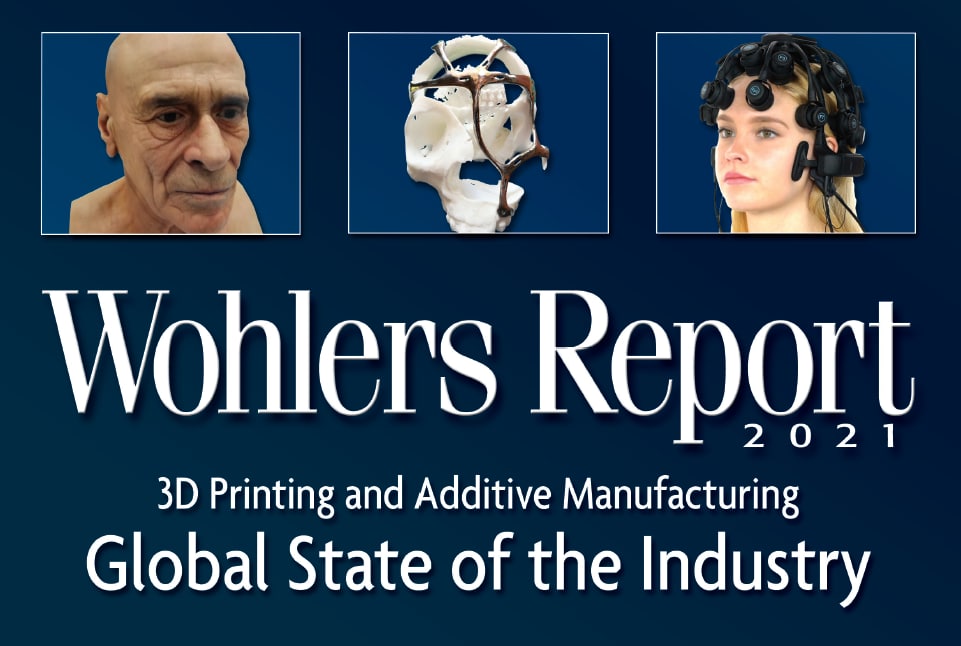

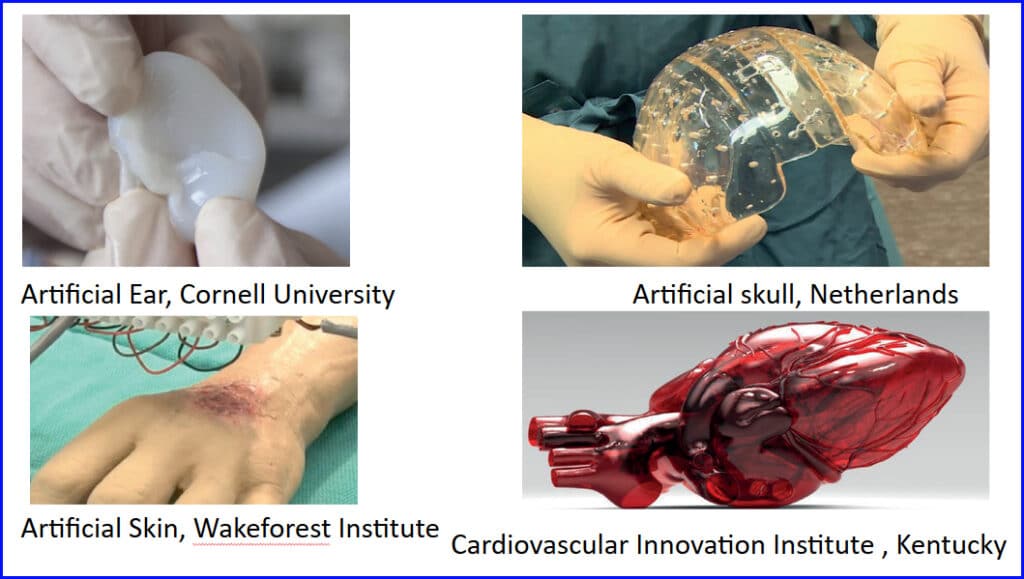

“Making” is not new. Most, if not all, cultures have some heritage of inventing, creating, modifying, repairing, enhancing products or something built by a person. Often, it is labeled as the Do-it-yourself (DIY) trend. Not too long ago, “Shop” class served as a place for people who liked to make things; it might have been wood shop, metal shop, or art class. When those programs experienced financial cutbacks, a vacuum grew, and the maker movement took its place, in many ways. Often, this was one or more people working in a garage or empty space that slowly filled with machines, newer machines, such as 3D printers, laser cutters, and Computer Numerical Control (CNC) machines (consider them an automated wood or metal router that follows computer directions on where and how to cut an object).

These new spaces, Maker Spaces, started to pop up in for-profit companies, non-profit corporations, organizations affiliated with or hosted within schools, universities or libraries, and more. The authors point out: “They are collaborative environments inside a university, school, library or dedicated public or private facility for learning, exploring, making and sharing, that use high-tech to no tech tools.”

Although many people consider a library a place for only books, that has not been the case for many years. Libraries are far more nimble and responsive to their communities and the authors cite another article: Change in the making: Makerspaces and the ever-changing landscape of libraries by Heather Moorefield-Lang, an associate professor in the Library & Information Science (LIS) Department at University of North Carolina at Greensboro (UNCG), who studies makerspaces within the library systems and how they can succeed and continue to change with the times.

In the Technologies article findings, “MakerSpaces are becoming an essential part of post-secondary education in supporting educational delivery. Their contribution to curricular and extracurricular delivery, hands-on learning skills and creativity is reported to be high. The iMakerSpace model focused on innovative workforce development in several curricular and extracurricular settings and proved that it has been very well received by students and educators, even under COVID-19 outbreak restrictions. Although there is still a need for more diverse manufacturing equipment, such as laser cutting machines, the reported activities and innovations of the iMakerSpace were proven to be beneficial to the users, and they are effective in engaging students and sustaining operations.”

The article is a valuable primer on the maker movement, makerspaces within a variety of communities, including public libraries, higher education, community centers, and occasionally on corporate campuses. Makerspaces, as the authors highlight throughout, are spaces where students and members have “an opportunity to participate in developing innovative projects… are empowered to use collaborative facilities and social connections, in addition to conventional instructional guidance and technical facilities to explore innovation.”

The authors surveyed participants to determine what makerspace users found the most beneficial to them, including, Workforce training, professional growth, networking, club activities, studying, and fabricating/3D printing.

COVID-19 slowed the in-person visits to the TTU iMakerSpace, but it did not slow the amount of 3D prints submitted to the space; in fact, the authors report that the number of prints actually saw a slight increase over the previous months, largely due to an increase in communication between college departments.

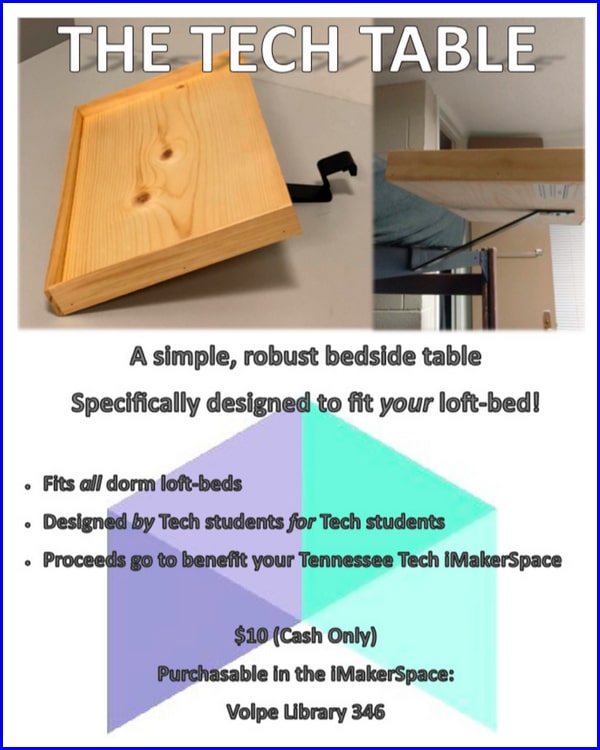

The space supports nearby and regional companies with small-scale parts, professors fabricate parts for research projects, and students design and prototype various products as they explore entrepreneurship and innovation. According to the article, “‘Tech Tables’ helped students to develop a product with a small-scale sustainability model. They were designed and fabricated to latch onto the side of [dormitory] beds and provide a handy charging station for cell phones and other personal effects. They are sold for USD 10 at the iMakerSpace and help fund the space. Image below.

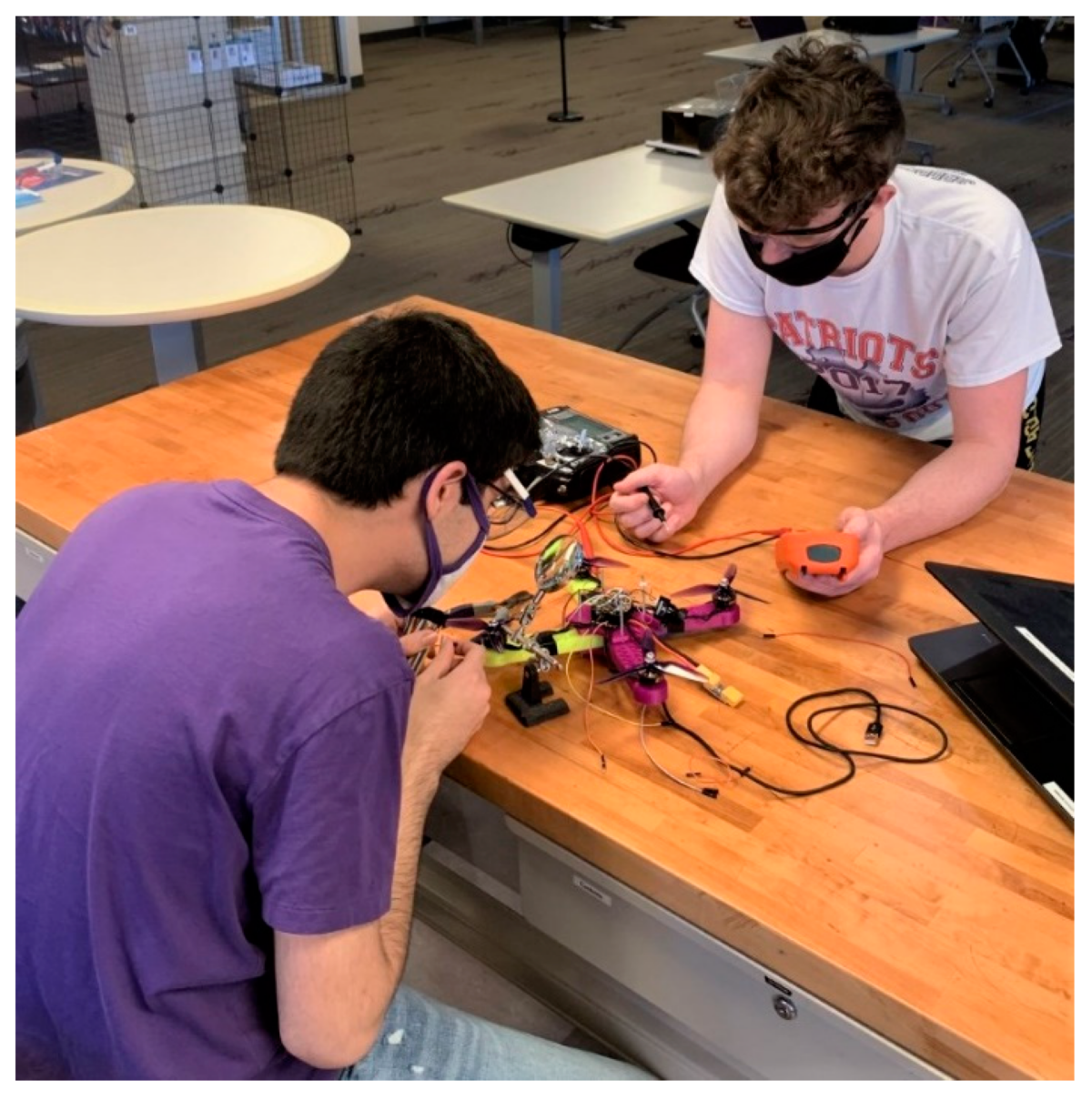

The Maker Movement and the growth in makerspaces might appear to have slowed down thanks to the pandemic, but that is not the case. Makerspaces are vibrant, still-growing, and adapting to the maker’s, the creator’s, needs and wants. Tenn Tech with its iMakerSpace is one of many leading the way to help other schools and libraries to keep guiding students to learn in what some consider non-traditional ways. This UNCG image on that school’s makerspace page captures the essence of what Dr. Ismail Fidan and team found in their research: “Not all individuals are able to learn from books; We need these hands-on opportunities for students to tinker and explore.”

Additional Resources You Can Use:

UNCG Exploratorium : Makerspaces

Drexel University report on “Making Culture”

Laura Fleming’s book: The Kickstart Guide to Making GREAT Makerspaces (no affiliate links)

Edmonds College, home of the NSF TEAMM project that publishes AM News, has a student and community makerspace, The Facility, that serves in a similar way as iMakerSpace and learned from its example.