Tennessee Tech University wants to make 3D printing accessible to more people. Dr. Ismail Fidan and a team of additive manufacturing (AM) experts contributed to a new Springer textbook: Cyber-Physical Laboratories in Engineering and Science Education, to show how they intend to make remote access to an AM lab possible.

Additive manufacturing, also known as 3D printing, continues to grow in popularity and as an approach to teach science, technology, engineering, and math (STEM). But the cost of the machines prohibits many educational institutions from purchasing, so Dr. Fidan and his colleagues pondered how they could grant remote access to more teachers and students. In this textbook chapter, the authors introduce a novel concept of accessing external AM laboratories via smartphones and advanced computer technologies.

The chapter, The Development and Implementation of Instruction and Remote Access Components of Additive Manufacturing, showcases the TTU Engineering department’s project to create a smartphone application that links AM labs to each other. It lists the pros and cons of contemporary practices to make a lab available online. The chapter also highlights the components and processes they used to build the lab and run it remotely. To broaden resources in AM teaching and workforce development, four institutions were part of the remote AM collaboration network project.

AM Remote Access Network: Technical Details

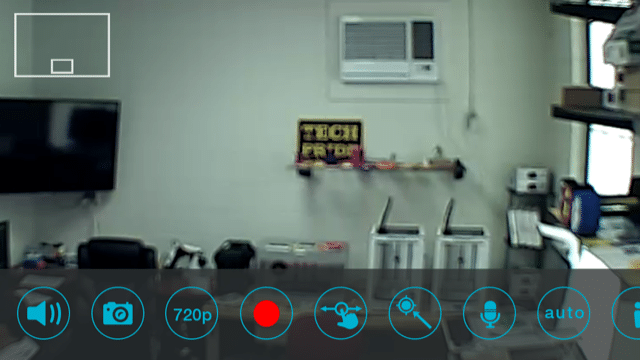

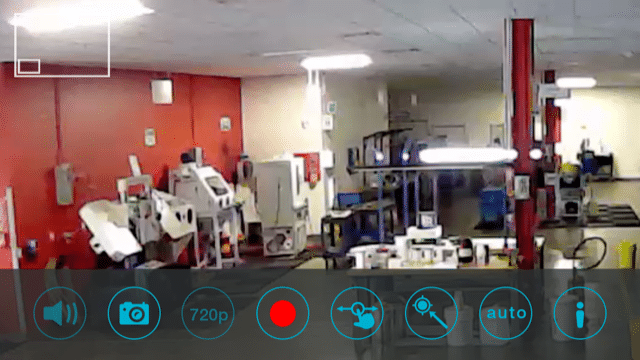

According to Dr. Fidan: “The AM Remote Access Network, AM laboratories are linked with exceptionally precise network cameras. All network cameras are equipped with two-way communication, infrared night vision, an SD card slot, digital zoom (x10), pan and tilt abilities, and motion alerts. They also have two-way audio connection, which is a useful feature that lets anyone chat with the laboratory personnel through the remote access. These cameras also let users monitor the part production from start to end and inform the laboratory personnel when there is an issue. Currently, the system does not provide any control on the design software tools, but lets the users access the laboratory, watch the production real time, and see the finished product without any delay.”

The TTU College of Engineering is proving that owning a 3D printer is not the only way to help your students create a 3D printed object. As part of their project, Dr. Ismail Fidan and team developed a remote-access smartphone application that made it easy to connect to the AM network and lab. In the future, more remote access networks and labs will be built giving teachers and students’ ways to test this method for their classrooms.

The chapter authors:

- Ismail Fidan, College of Engineering, Tennessee Technological University, Cookeville, Tennessee, US.

- Amy Elliott, Manufacturing Demonstration Facility, Oak Ridge National Laboratory, Knoxville, Tennessee, US.

- Mel Cossette, National Resource Center for Materials Technology Education, Edmonds Community College, Lynnwood, Washington, US.

- Thomas Singer, The Science, Mathematics and Engineering Division, Sinclair Community College, Dayton, Ohio, US.

- Ed Tackett, J B Speed School of Engineering, University of Louisville, Louisville, Kentucky, US.

The Springer textbook, Cyber-Physical Laboratories in Engineering and Science Education, editors:

- Michael E. Auer, Carinthia University of Applied Sciences, Villach, Austria

- Arthur Edwards, University of Colima, Colima, Mexico

- Abul K.M. Azad, Northern Illinois University, DeKalb, IL, USA

- Ton de Jong, University of Twente, Enschede, The Netherlands

Acknowledgements: This work is part of a larger project funded by the Advanced Technological Education Program of the National Science Foundation, DUE #1601587.